AAC All Aluminum Conductor

AAC All Aluminum Conductor

What’s the AAC Conductor?

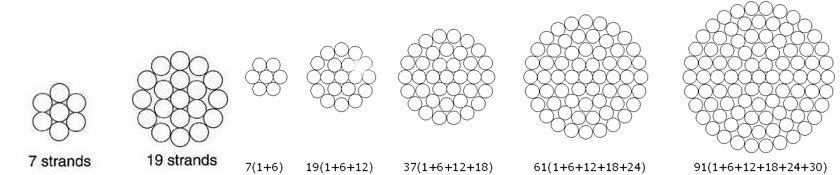

AAC conductor is also known as aluminium stranded conductor.

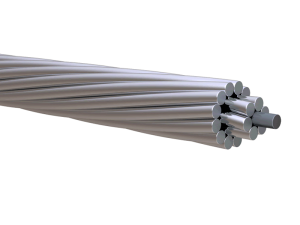

Concentric lay stranded Aluminium Conductor ( AAC) is made up of one or more strands of hard drawn 1350 aluminum alloy. These conductors are used in low, medium and high voltage overhead lines,and it is one of the main products to form electrified wire network.

AAC (all aluminum conductor) is the most economical bare overhead conductor due to its lighter weight. It offers easier handling during installation and use of simpler fittings. The wire is corrosion resistant due to its homogeneous construction.

JYTOP can manufacture & supply AAC on Non returnable wooden/steel reels or Returnable steel reels.

AAC All Aluminum Conductor

AAC All Aluminum Conductor